Control Board Assembly used to control and regulate modern electronic devices

Control board assembly is a critical process in electronics manufacturing that involves assembling components onto a control board to manage and regulate the operation of electronic systems. From industrial automation to consumer electronics, control board assembly plays a vital role in ensuring precision, reliability, and performance in modern devices. As technology advances, the demand for high-quality control board assembly continues to grow across multiple industries.

What Is Control Board Assembly?

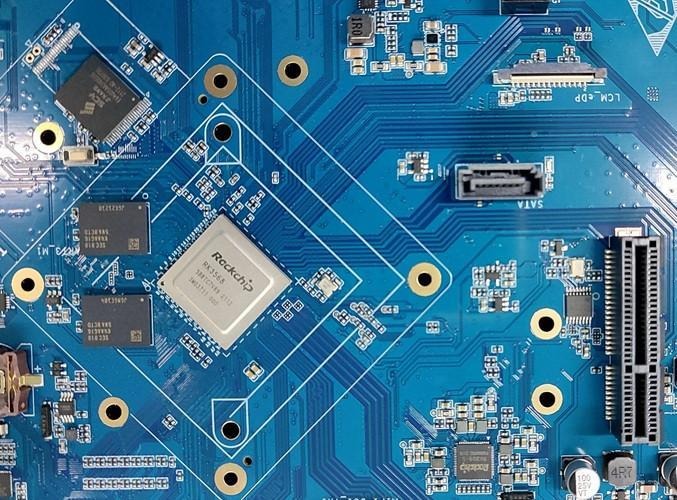

Control board assembly refers to the process of manufacturing and assembling electronic components onto a control board that acts as the central controller of a device or system. The control board processes signals, executes commands, and coordinates various functions within electronic equipment. It typically includes microcontrollers, sensors, resistors, capacitors, integrated circuits, and communication modules.

In modern electronics, control board assembly is designed to meet specific functional requirements, making it highly customizable for different applications and operating environments.

Key Components in Control Board Assembly

Control board assembly involves a combination of hardware components that work together to ensure smooth system operation. Microcontrollers serve as the brain of the control board, while power management circuits regulate voltage and current. Communication interfaces enable data exchange, and protective components ensure safety and durability.

The integration of these elements during control board assembly determines the overall performance and reliability of the final product.

Control Board Assembly Process

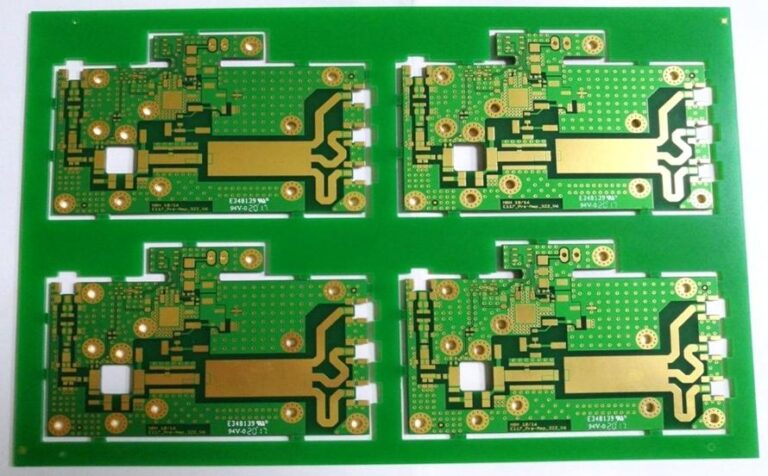

Design and Engineering

The control board assembly process begins with circuit design and engineering. Engineers define system requirements, select components, and design the PCB layout to ensure optimal functionality and signal integrity.

Component Placement and Soldering

During control board assembly, components are placed onto the PCB using automated SMT machines or manual techniques for specialized parts. Soldering methods such as reflow soldering and wave soldering are used to secure components.

Programming and Firmware Integration

Programming is an essential step in control board assembly. Firmware is installed to enable the control board to perform specific tasks and respond to system inputs.

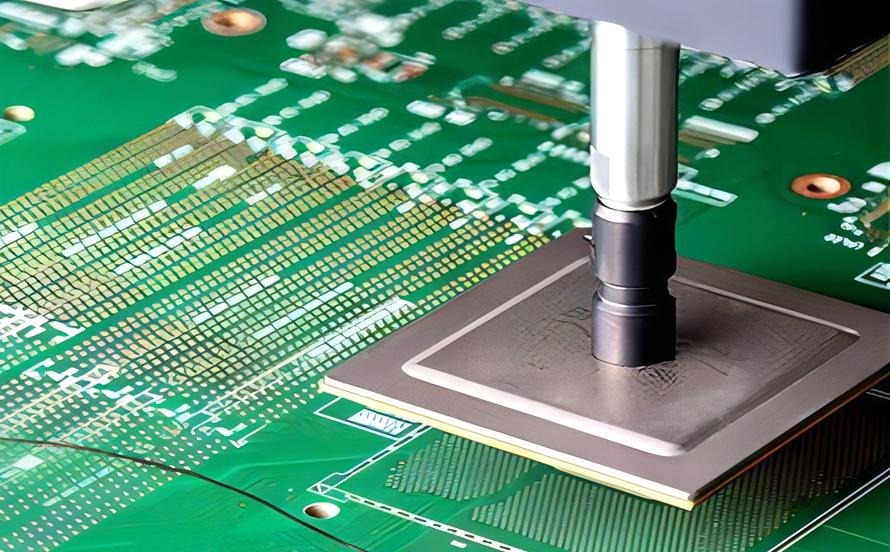

Testing and Inspection

Quality control is a crucial part of control board assembly. Functional testing, electrical testing, and visual inspection ensure that the control board meets design specifications and industry standards.

Final Assembly and Integration

After testing, the control board is integrated into the final product or system. This step completes the control board assembly process and prepares the product for real-world applications.

Advantages of Control Board Assembly

Control board assembly offers several advantages, including improved system performance, enhanced reliability, and reduced operational errors. By using advanced manufacturing techniques, control board assembly ensures consistent quality and scalability for both low-volume and high-volume production.

Additionally, control board assembly enables customization, allowing manufacturers to develop tailored solutions for specific industries and applications.

Applications of Control Board Assembly

Control board assembly is widely used in industrial machinery, automotive electronics, medical devices, home appliances, telecommunications equipment, and smart devices. In industrial automation, control board assembly ensures precise control of machinery and processes. In consumer electronics, it enables intelligent features and user-friendly functionality.

Challenges in Control Board Assembly

Despite its advantages, control board assembly involves technical challenges such as component compatibility, thermal management, signal interference, and compliance with regulatory standards. Addressing these challenges requires expertise in design, manufacturing, and quality assurance throughout the control board assembly process.

Future Trends in Control Board Assembly

The future of control board assembly is shaped by advancements in artificial intelligence, IoT, and smart manufacturing. As devices become more intelligent and interconnected, control board assembly will evolve to support higher performance, miniaturization, and energy efficiency.

Conclusion

Control board assembly is an essential part of modern electronics manufacturing, enabling precise control and reliable operation of electronic systems across industries. To achieve high-quality results and scalable production, it is crucial to work with a trusted PCB assembly company that offers advanced manufacturing capabilities, strict quality control, and end-to-end support for customized control board assembly solutions.